1. Sewage Treatment System Based on Membrane Bioreactor Technology(MBR)

General Description of Membrane Bioreactor System Technology

We provide solutions for packaged and modular MBR systems starting from 10M3/Day up to 600M3/Day as Standard units.As shown in the Figure,both the conventional treatment and the Membrane Bioreactor System processes are based around the well-proven activated sludge process to biodegrade the organic material present in waste water streams from municipal, industrial and/or commercial development activities. However, unlike conventional activated sludge (CAS) treatment, which employs a clarifier or sedimentation tank to separate the biomass solids from the treated water, the Membrane Bioreactor System employs a significantly more effective & efficient membrane as the solids liquid separation mechanism.

In the Membrane Bioreactor System process, effectively screened (/=2 mm punched-hole fine screen) wastewater flows or is pumped into the lead end of the biological treatment vessel. The oxygen requirements for the aerobic zone of the biological process are typically provided by a fine-bubble, diffused-aeration system.

From the biological process, the partially treated wastewater flows into the aeration tank. The membranes are incorporated directly into the aeration tank.

Within the membrane separation process, and integral to the membrane module, a coarse bubble aeration system is used to continuously scour bio-film off the membrane surface area and move the more concentrated MLSS away from the immediate vicinity of the membranes. From the membrane separation, treated permeate is drawn through the membrane by suction pump (filtered water pump) with a driving force the membrane [trans membrane pressure (TMP)] of usually less than 20kPa for Membrane Bioreactor System, the energy of the permeate system are minimal.

Finally, the treated permeate is drawn through the membrane by filtered water pumps and discharged to the receiving environment.

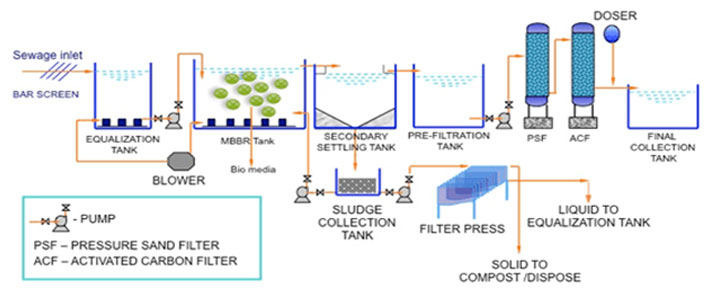

2. Sewage Treatment System Based on Moving Bed Bioreactor Technology (MBBR)

We provide solutions for packaged and modular MBBR systems from 10M3/Day up to 500M3/Day as standard units. Moving Bed Bio Reactor(MBBR) incorporates the advantages of attached film technologies and combine with them the coarse/fine bubble diffused aeration techniques,to get a highly efficient biological treatment unit.

With the higher surface area of BIO media, higher organic loading rates are enabled, thus reducing the overall size required of the aeration tank. This leads a considerable reduction in civil & Fabrication costs.

The system configuration enables better oxygen transfer efficiency with plug flow conditions.Submerged floating film growth in MBBR reactors sustain good microbial growth even in adverse conditions and also handles shock loads without affecting the process. Sludge production is lower compared to other conventional technologies.