1. Ultrafiltration/Microfiltration Systems

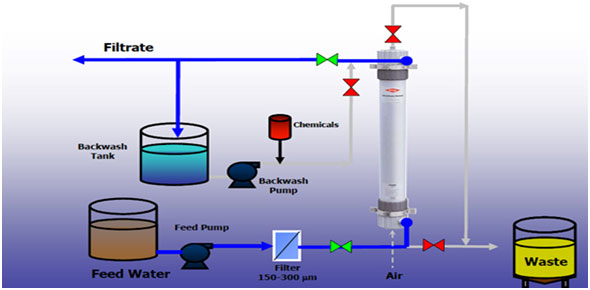

We provide packaged and modular Ultrafiltration/Microfiltration Plant(UF/MF) from 50M3/Day up to 5000 M3/Day as Standards. Ultrafiltration/Microfiltration can be used as a pre-treatment for sea water application, Grey Water and TSE application Ultrafiltration membrane module

Range of ultra-filtration process

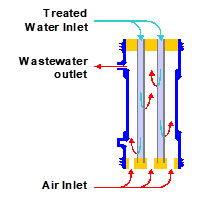

Water from automatic strainer enters to the supply manifold of the membrane module. All membrane modules are installed in parallel to get the equal supply of the feed water.

Production cycle

Pressure is applied to the water via feed water pump and this forces the water to pass through the pore of the hollow fibre to enable filtration. The pressure and flow at the membrane surface is controlled at the desired set point to achieve the designed flux on membrane modules. Variable frequency drive operated feed water pump controls the feed water flow to maintain the filtrate flow rate continuously for 20 – 30 min operation period regardless of pressure drop across the membrane which will result more pressure requirement from the feed pump. Feed water pump variable frequency drive is connected to flow transmitter which will keep constant flow rate during the production cycle. Production cycle is normally for 20 – 30 min depending upon the quality of feed water.

Flux Maintenance

Periodically each membrane rack goes through the automatic flux maintenance/Maintenance Cleaning cycle. This consists of simultaneous air scrub – reverse filtration cycle followed by feed flush (FF) to remove the particles and organic matter accumulated on the surface of membrane modules.

During this process, the compressed air bubble outside the fibre shake them vigorously. This loosen particles adhere to the fibre skin. All waste produce is diverted to the drain. At the end of this process feed water is introduced to the UF/MF module and first quantity is also routed drain. Flux maintenance cycle is after a cycle of production at 100% recovery and will be for 0.3 -2.0 minutes duration and will be automatically controlled via time cycle as well as differential pressure monitor across the membrane module.

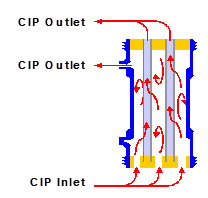

Clean In Place

Every so often the system will require a more thorough cleaning then cleaning process can be applied. This requires a maintenance cleaning step, also called a clean in place (CIP). Cleaning chemicals are added to the system and circulated as required to regenerate the module. CIP normally takes 2- 3 hour to complete the process and this includes cleaning, circulation, soaking and flushing of chemicals to enhance the flux of membrane modules.

2. Multimedia/Pressure Sand Filter/Activated Carbon Filters

We provide solutions for filtration systems like Multimedia/Pressure Sand Filter/Activated Carbon Filter (MMF/PSF/ACF) from 50M3/Day up to 5000 M3/Day as Standards. These filters can be used for Potable water/Sea water/Grey Water/Sewage/TSE applications. Material of construction shall be frp, carbon steel, stainless etc., depending upon the application.